Dongguan World Strong rubber company has 6 advanced rubber compounding machines, 43 rubber flat vulcanizing machines, 50ton-300ton, 20 liquid silicone rubber injection machines, the maximum processing range: 1200 * 750mm, 6 liquid molding machines, 2 internal mixer, etc. the company has a complete set of silicone rubber testing equipment, which can independently design and develop new materials to meet the specific requirements of customers.

The main materials: Gel,NR,NBR,EPDM,SBR,CR,IIR,PU,CSM,BIIR,HNBR,FKM,AFLAS, LSR, HTC, RTV-1, RTV-2, etc.,At the same time, the company has 8 precision crosscutting machines and punches, and uses materials such as sponge, Mylar, PORON, adhesive tape, insulation / conductivity to process, computer, mobile phone, camera and other consumer e-mail die-cutting products. Specializing in the production and processing of auto parts silica gel, medical silica gel, consumer electronics silicone rubber, bathroom silicone rubber, e-mail silicone rubber products, our own mold room, our company can use copper inlay or discharge process according to the product design requirements, now the success rate of mold opening is more than 90%, the product molding experience is rich, the molding efficiency is high, for the rubber formula proportion and molding conditions are very good Grasp, can ensure continuous hair, hair does not deform, welcome to process customized.

PARTNERSHIP

Innovating Customization with a Premier Silicone Factory

We delve into the fruitful partnership between our esteemed silicone factory and a distinguished American silicone products company. Together, we embarked on a trailblazing venture to create a captivating line of unique silicone products, achieving notable strides in brand promotion and market expansion. This case study stands as an inspiring testament to the power of collaborative endeavors within our industry.

Amidst the landscape of silicone product manufacturing, our reputable silicone factory stands as a vanguard of innovation. Dedicated to crafting imaginative, top-tier silicone cups, lids, wine glasses, and beyond, we have garnered recognition across various sectors, ranging from outdoor to home and dining.

Well-known Baby Plate Customization Experience

Working with well-known brands that focus on baby feeding products,support one stop service in satisfying our clients with high quality and custom-made silicone baby products,constantly cooperate with customers for innovative development.

Liquid silicone baby plate with the stable suction cup and separation function, let the baby enjoy the food while helping parents train the baby’s ability to eat.It’s also very practical,environmental protection,non-toxic, safe and assured.

All products are using ultra-soft liquid silicone, are customized by the world’s leading organic silicon manufacturer Germany Wacker strategy, closer to the softness of the skin.We also strictly control, selected the world’s largest testing agency SGS for its safety testing. From the source to the production, from the factory to the supply and demand, XHF assists the brand to check the safety of the baby.

OUR PRODUCT

Molding:

was first set up in the early of our company, now has 300 employees, more than 60 sets various sizes and advanced production equipment, and a professional team of more than 30 senior engineers, with excellent technology and excellent quality walk in the front end of the industry. Including silicone kitchen products, baby products and outdoor silicone products, and military industry and new energy automobile and on various silicone product domain.

LSR Injection:

Liquid Injection is a very important department of our company, it has a 300,000-class dust-free workshop, with 20 sets imported high-end precision liquid machinery and supporting equipment, the total number of outstanding staff up to 60 people in liquid silicone injection department, to provide customers with better quality, more sophisticated medical grade baby products and medical supplies!

Plastic Products:

Plastic department is a supporting department for our company to make plastic and silicone combined products, with a team total of more than 30 employees, more than 10 plastic machines and supporting advanced equipment. To meet the one-stop demand, for efficient, integrated production mode cushion set a solid foundation! It’s enough to make independent research and development and innovation!

Mold Development:

The mold department is fully equipped with a series of precision equipment, which is a collection of research and development, design, production integration company, in order to achieve the design concept, independently set up the mold development, with CNC and a variety of precision equipment, from the design concept to the physical sample has an independent and efficient mode,perfectly guarantee the timeliness of the product on the market!

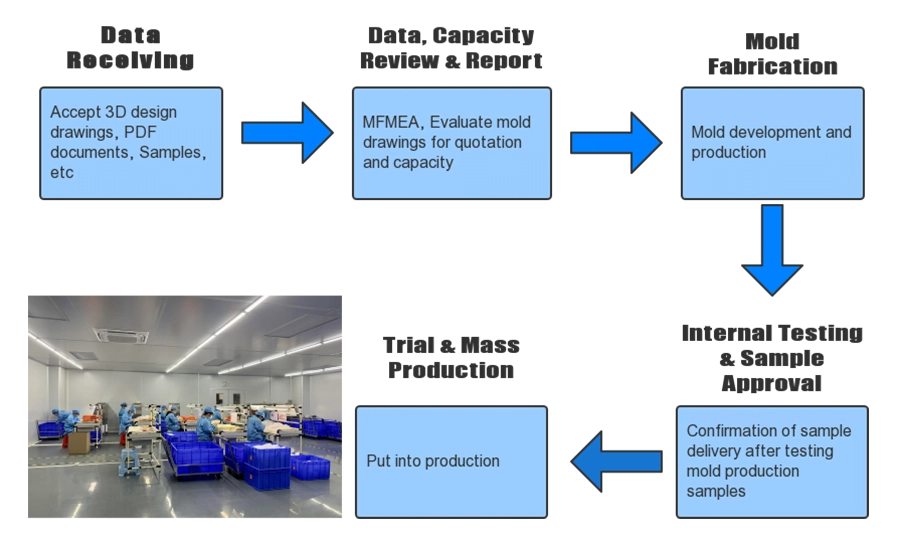

One-stop OEM/ODM Service for Silicone Products

WS Silicone Manufacturing Co., LTD, is a manufacturer of silicone products. We have 25 years of experience in the silicone product industry, which can provide you with a comprehensive solution, including research and development, design, production, etc. Our product range includes silicone industrial accessories, household products, baby products, and medical products.

We can provide you with customized services, including compression molding, (LSR) liquid injection molding, plastic product supply, and mold development; We can bring your silicone product ideas to market.

Reasons for Choosing WS OEM&ODM Silicone Products

OEM&ODM Experience

You only need to provide samples and drawings; we provide you with one-stop OEM&ODM service (solution, manufacturing, testing, mass production).

Professional Services

We has been specializing in silicone products for 25 years, and our professional foreign trade team is committed to providing you with a satisfactory customized service.

Environmental Certification

We has passed ROHS, REACH, FDA, and LFGB certifications, and 90% of our products are exported to Europe and America.

Quality Assurance

We has a dust-free workshop and environmental protection system; we conduct in-house tests before delivering our products to ensure quality of our products.

MAIN PRODUCTS

Silicone Baby Products

Silicone Kitchen Utensils

Silicone Components

Silicone Medical Supplies